Controllers.

Controlling precise machinery is a big task, especially when it comes to doing it quickly and efficiently. It takes a huge processing power to move several motors and even more if they are working together on a single job. Thats why we offer several options of controllers to better accommodate your needs.

Here are some of these options…

GSK controls have gained popularity all over the world, especially in United States. They are made from top quality Chinese manufacturing and engineering, offering a great deal of reliability and cost efficiency.

If you have worked with Fanuc controls before, you will find GSK just as easy to use.

Robust controllers for handling industrial machinery, ideal for lathes, mills, plasma cutters, and more.

CONTROLLER MODELS

MILLING & DRILLING

* Pitch Error Compensation

* Tool Wear Compensation

* Backlash Compensation

* Tool Nose Radius Compensation

The system has DNC control and its baud rate can be set.

Perfect Control for machine centers and general milling. with the possibility to use 4 axis, the control is able to adapt easily to servo motors.

GSK 218 MD

4 ANIX / 3 LINKS

MILLING

* Pitch Error Compensation

* Tool Wear Compensation

* Backlash Compensation

* Tool Length Compensation

* Tool Nose Radius Compensation

Perfect Control for machine centers and general milling. with the possibility to use 4 axis, the control is able to adapt easily to servo motors

GSK 218 MC

4 Anix / 3 Links

MACHINING

* Pitch Error Compensation

* Tool Wear Compensation

* Backlash Compensation

* Tool Length Compensation

* Tool Nose Radius Compensation

GSK 96

3 AXIS / 2 LINKS

MILLING & DRILLING

* Pitch Error Compensation

* Tool Wear Compensation

* Backlash Compensation

* Backlash Compensation

* Tool Nose Radius Compensation

480×234 7″ color LCD English/Chinese LCD display. 5 controllable/ 3 linkage axes. Two analogue spindle interface. 0.0001mm precision. 60m/min rapid traverse speed. USB function Tapping, 22 kinds of milling, drilling, tapping cycle dictate Parameters programming suitable for special purpose Optional DNC function to finishing complex machining with CAM Changeable shifting time fitting in with servo or step driver system. Actual adjustable feed speed ratio . Optional electronic hand wheel.

GSK 980 MDa

5 Axis / 3 links

DRIVER MODULES & SERVO MOTORS

SERVO DRIVER MODULE

* The exclusive DSP and intellective IPM module for the motor control with high integration and excellent reliability;

Rated Output Power: 2.6KW (3.4HP)- 3.5KW / 3.5KW – 6.0KW

Input Power: Single phase or 3 phases AC (0.85~1.1)×220 V 50Hz/60Hz

Feedback Pulse: 10000 pulse/rotation

DA01B

State Monitoring

SERVO AC SPINDLE DRIVE

GS3000Y

New industrial IPM module

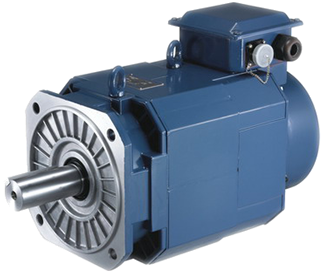

ZJY Series

Hasta 27.5 Nm de torque

SERVO DRIVE MODULE DRIVE

* High performance rare earth permanent magnet material, high power, large load

Continuous Power Output: 0.5KW – 6KW

Input Power: Single phase or 3 phases AC (0.85~1.1)×220 V 50Hz/60Hz

Vibration : ≤ 0.6G (5.9m / s2)

Encoder Feedback : 5000 pulse/rotation (Resolution 10000) Incremental Encoder

GS2000T

Ultra Strong Overload Capasity